An Unbiased View of Hot Runner Systems

According to this third element of today invention, a flow rotator for rotating a cross-sectional asymmetrical condition of a laminar flowing material is provided in a warm jogger system for supplying a laminar flowing material. The hot runner system has (i) an upstream melt flow, (ii) a set of intermediary melt flows downstream from the upstream thaw passage, and also (iii) for a minimum of one intermediary thaw flow, a connected pair of downstream melt passages downstream from the at the very least one intermediary thaw flow.

BRIEF SUMMARY OF THE DRAWINGS For a better understanding of the here and now innovation and to show even more plainly how it may be lugged right into result, recommendation will certainly currently be made using instance to the going along with illustrations, revealing short articles made according to a preferred personification of the here and now innovation, in which: FIG.

1 b, in a schematic profile, illustrates a warm jogger manifold based on the prior art; FIG. 2 is a sight on A-A of FIG. 16; FIG. 3, in a sectional view, highlights the melt flow in a main jogger of the hot runner manifold of FIG. 1 b as it branches right into a set of second runners; FIG.

16; FIG. 5, is a sight on C-C of FIG. 16; FIG. 6, in a sectional sight, illustrates the thaw circulation of FIG. 4 as the second runner branches into a pair of tertiary runners; FIG. 7, is a sight on D-D on FIG. 1 b; FIG. 8, is a view on E-E of FIG.

9 Easy Facts About Hot Runner Systems Shown

9, is a sectional sight on p-p of FIG. 10 a flow-rotating plug based on a personification of the innovation; FIG. 10, in a perspective view, highlights the flow-rotating plug of FIG. 8; FIG. 11 a, in a side sight, highlights a part of a pile mold and mildew having the plug of FIG.

Unknown Facts About Hot Runner Systems

23; FIG. 25, is a view on M-M of FIG. 23; FIG. 26, is a sight on N-N of FIG. 23; FIG. 27, is a sight on O-O of FIG. 23; FIG. 28, in a schematic sight, illustrates a hot jogger system incorporating a complementary plug based on a further element of the present creation; FIG.

28; FIG. 30, is a view on M ′-M ′- of FIG. 28; FIG. 31, is a sight on N ′-N ′ of FIG. 28; and, FIG. 32, is a view on O ′-O ′ of FIG. 30. IN-DEPTH SUMMARY OF THE INVENTION Describing FIG. 1 a, there is shown in a side sight, a part of a stack injection molding device 10 in accordance with the previous art - hot runner systems.

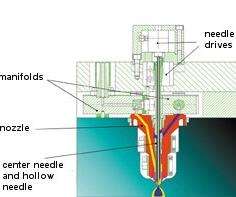

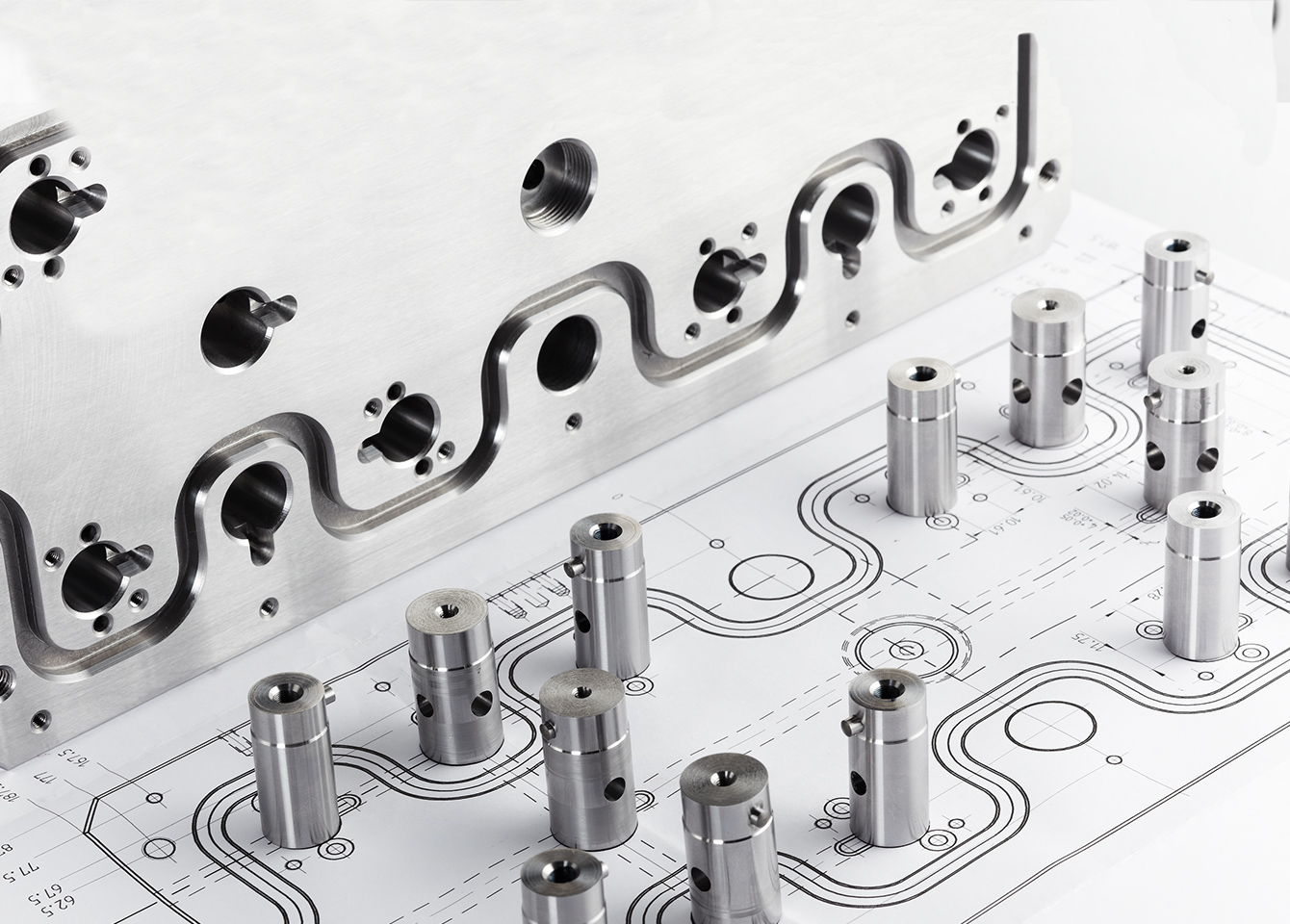

The jogger system 12 consists of a main runner 16 for obtaining melt from a melt resource (not shown). At a very first branch 18, the primary runner 16 branches right into 2 additional joggers 20. The secondary runners 20, at respective second branches 22, then branch into tertiary runners 24. The tertiary runners 24 supply melt to associated nozzles 26, which inject the melt into connected mold dental caries (not revealed).

1 b, there is illustrated in a profile, a manifold 14 b of a shot molding apparatus 10 b according to the previous art. The manifold 14 b consists of a jogger system 12 b. The runner system 12 b consists of a main jogger 16 b for getting melt from a melt resource (not shown). FIGS. 2-8 are explained relative to the manifold 14 b only for simpleness. Describing FIG. 2, there is shown a sectional view of key runner 16 b at A-A of FIG. 1 b. A warmed peripheral portion 28 of the melt around the jogger wall of the key runner 16 b is shown by shading.

The Ultimate Guide To Hot Runner Systems

2, the hotter thaw adjacent the jogger wall is significantly uniformly distributed regarding the jogger wall surface. At the first branch 18 b, the warmed outer portion 28 of the flow is separated right into two, as received FIG. 3. Each of these halves of the warmed periphery then flows right into the additional joggers 20 b of the manifold 14 b.

find here address click to find out more